Building Wire Extrusion Line

Building Wire Extrusion Line

Building wire extrusion Line which are able to carry our different process as: Single layer, Co-extrusion, tandem extrusion, our machine ensure high productivity and unexpected line speed due to the flexibility of our lines due to our wide range of pay-offs and take-ups.

Extrusion Machine Electric Control:

Siemens PLC + HMI control the whole stranding line.

70 Building Wire Extrusion Line

Building Wire Extrusion Line

Description:The Building Wire Extrusion Production Line is suitable for several thermoplastic compounds such as PVC, PE, XLPE and LSHF.

Features:

1. Building Wires insulation lines suitable for several thermoplastic compounds extrusion such as PVC, PE, LDPE, XLPE and LSHF.

2. Co-extruder for color skinning & stripping purposes can be as an option for the insulation line.

3. Line can be completed with THHN insulation by including a tandem extruder for PA (Nylon) outer jacketing| Sheathing.

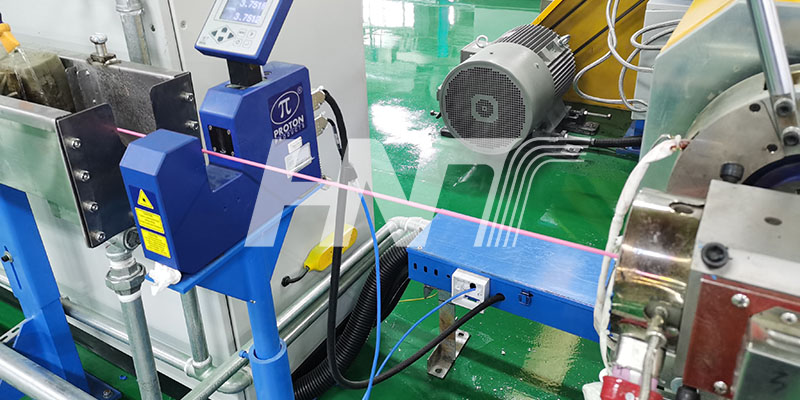

4. HMI+PLC control, wire dia. testing, line speed, spark testing, all the line process parameters can be modified, stored, adjusted on the trouch screen and it is convenient for operation.

5. Different take up devices can be configured as required according the line speed. Such as the dual takeup, Semi-Auto takeup or cable coiling and packing line.

6. These machines can be selected according to your requirements: automatic feeding machine, vacuum dryer, masterbatch machine, wire diameter tester, inkjet machine (laser, ink), frequency spark tester and other auxiliary machines.

Technical Parameters:

| Model | Screw Parameter Dia.(mm) L/D Speed(RPM) |

Max Extrude capacity (kg/hr) PVC LDPE LSNH |

Finished OD (mm) |

|---|---|---|---|

| EX-40G | 40 26:1 120 | 24 14 | 0.8-3 |

| EX-50G | 50 26:1 120 | 60 36 | 1-6 |

| EX-60G | 60 26:1 120 | 100 60 22 | 2-8 |

| EX-70G | 70 26:1 120 | 160 130 36 | 3-15 |

| EX-80G | 80 26:1 110 | 220 180 48 | 5-20 |

| EX-90G | 90 26:1 100 | 310 240 65 | 8-25 |

| EX-100G | 100 25:1 90 | 400 90 | 10-30 |

| EX-120G | 120 25:1 90 | 550 | 15-40 |

| EX-150G | 150 25:1 60 | 900 550 | |

| EX-200G | 200 25:1 60 | 1300 1100 750 |